On-demand products, customized goods, a new industrial revolution—people are pinning huge expectations on 3D printing, but can the reality meet the hype?

I discussed the future of the technology with the two men behind Make Mode, a Brooklyn-Based digital design and fabrication studio. Founded in 2012 by childhood friends Austin Robey and Blair Gardner, Make Mode has worked with Bloomberg, MetLife, Barneys and others to bring their design ideas into reality—often with the aid of 3D printers. Together, we judged a few popular predictions for the future of 3D printing.

Within the next 10 years, will 3D printers and scanners be common in households?

Blair Gardner: Nah.

Austin Robey: I don’t think households have found a useful enough application for them to take up the real estate.

BG: A lot of people think, “Oh, I can 3D-print a dial for my broken washing machine.” It can be useful to have that kind of thing, but the costs of getting a 3D printer and the time it takes to learn the software, to debug it — now and for the next 10 years—does not make it practical to have something in your house for those uses … It would be more likely that there’s somewhere in the city that can print it for you and you send them the file and go pick it up after work or whatever.

Something like Kinkos?

AR: I would hope that it’s something better than Kinkos.

BG: Speed is still a huge issue. You can’t just go in and 3D-print something and leave in five minutes. With current technology, if you want to print something that’s four or five inches high, it’s going to take four or five hours. So it’s already going to be at least two visits: one to set it up—or, you know, the first step could be online—and then another to pick up the print when it’s ready. But I would be surprised if in 10 years we didn’t see things like that emerging.

AR: The most exciting possible shift is taking the way manufacturing works and inverting it so there’s a possibility of making products on demand much closer to the point of consumption.

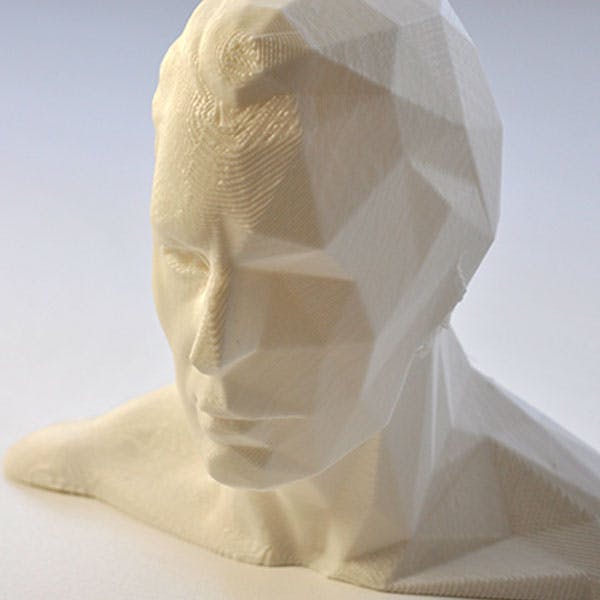

It’s going to leave the realm of prototyping, which seems to be where it is now.

AR: Yeah. That would be the biggest jump: going from prototyping to actual products. There’s so many limitations now that it’s a big design challenge to make a product that people want to buy based on what comes out of a 3D printer. But I think that design challenge will become much easier once the machines catch up.

BG: You’re seeing it now. One of the machines that we’re getting is full color, but it prints in a fragile-ish, brittle sandstone material. You can’t drop it; you can’t get it wet. But just this year they already announced a new printer that does full color in plastic. So now you have that ability to make things realistic, more life-like with color, but also in a much more useable material that is not going to break when you drop it nor melt in the rain.

How much faster do you think design and printing are going to be in the next 10 years?

AR: Coming from a design background, I don’t see design getting much quicker because you’re still using a human brain.

BG: But the software will be more accessible.

AR: I think it would be nearly impossible to boil those programs down into something that’s super simple because you want to be able to do a lot of things. You lose control once you start making it simple … The tools may help learning how to design be more intuitive, and then the printing will definitely be faster. The actual manufacturing will be much faster.

A matter of minutes?

AR: At some point. I don’t know if it’s 10 years, but at some point definitely.

What about scanning?

AR: That is something where the software will make a big difference.

BG: People are using 3D scanners a lot right now.

AR: Yeah, but the raw data you get from them is so messy. It’s never even ready to print. It’s barely ready for adapting.

Do you see that improving?

AR: Yeah, I could see that improving a lot. But again, those are like super, super technical backend questions for software developers. Everybody’s waiting on the software engineers—

BG: —and the material scientists and hardware engineers.

What do you think is going to change in terms of materials?

BG: They’re already looking into embedding circuitry, to 3D-print circuitry into objects. You’ll be able to use lots of different types of materials in a single printer.

AR: Yeah, multi-materials that can pass off as a finished product.

Right now you’re restricted to polymers?

AR: Basically plastic or plaster.

BG: Or metal.

My understanding is that right now you’re mapping things in 3D, where soon you’ll be able to build them?

BG: It’s polygon versus pixel.

AR: It’s a very technical answer, just in the way the files are constructed. There are NURBS, which stand for “Non-Uniform Rational B-Spline,” which is different from meshes. Meshes aren’t necessary solid; they’re just a series of two-dimensional triangular planes that have to be closed in order for the computer to say, “Oh, this is a solid object.” So if one of those triangles is missing the computer becomes really confused, and designing that way is hard. But if things are constructed from a unit that already is a solid, then there will be a lot less troubleshooting.

What about medical applications for 3D-printing?

BG: It’s a super custom area, right? Everything’s got to be custom-made for medical applications. [3D printing is] huge right now for prosthetics. Custom-printed prosthetic legs are those one-off, highly customizable things.

AR: We represent product more than medical or organic. The food stuff is not really design; it’s science. It doesn’t even seem like 3D printing to me. I get frustrated that it’s thrown in the same category.

I can print a Pikachu, but I don’t own the intellectual property behind that brand or that character.

Outside of making a custom cap for your wedding cake, do see any practical application for 3D printing food? Do you think that’s going to take off?

AR: I personally don’t … I haven’t heard of any actual killer application for 3D printing food beyond it just being something that people would blog about and something that sounds interesting.

BG: Outside of a really special event, I’m not sure how much people care about their food and having their name on it … It’s like artwork. To the sense that people care about and appreciate artwork, you can sort of view it the same way as custom designing and 3D printing something in sugar or chocolate.

AR: There could be environmental impacts. Considering that raising livestock causes most of our global warming, if you could print meat, that would make a difference.

BG: I wouldn’t publish any of this talk about printing meat.

Are you ever going to be ordering a table that was 3D-printed in your neighborhood?

BG: I would love to see that happen.

AR: I don’t think that is that crazy.

Do you think it’s likely?

AR: I think it’s likely. Maybe not a table, but maybe I’ll be proven wrong. I could imagine things like custom earbuds.

BG: They’re already doing that, custom eyewear, custom clothing. It’s going to come full circle: Before mass manufacturing, anything that you wanted was a bespoke product, it was made for you. With mass industrialization you want to make a lot of things because it makes it cheaper to make that thing. As 3D technology advances it becomes much cheaper to have complexity and customization, and it doesn’t cost more to print out anything that’s custom for you or a thousand slight variations on the product.

AR: It’s still just waiting for the machines to catch up. It’s such a design challenge to create a product from the existing printers right now. Creating a product that people even care to customize is a big challenge.

How much is technology being held up by patents?

AR: Some of the printing methods, like laser sintering machines, those machines cost about a quarter of a million dollars. The patents are expired on those, and now you’re starting to see people trying to make them for like $20,000, $30,000. It’s for sintering nylon, which has a lot of material properties which are really well-suited for what people want to do. That’s definitely a printer we would like to have, but the idea of spending a quarter of a million dollars on something that has a good likelihood of becoming obsolete in the next six months is kind of terrifying.

BG: You think six months? I’d give that a couple of years.

AR: OK, 2016.

BG: What’s also interesting for the 3D printing space is how patent law impacts not only the technology behind it but the goods. I can print a Pikachu, but I don’t own the intellectual property behind that brand or that character.

Have there been issues?

BG: Well Shapeways is actually starting to work with some companies who leverage their intellectual property for designs. They’re allowing people to print My Little Pony stuff because they struck a deal with the My Little Pony people saying these people can do this.

AR: Once the machines catch up, that’s going to be a gigantic issue. If and when you can create finished products off of a printer, then all of a sudden it’s like Napster or Pirate Bay or how people downloading MP3s totally changed the music industry. It’ll change the way people make physical goods. Another prediction I have is that there will be product streaming services. Instead of downloading a file to print something, you can pay to download that file and print it once.

That’s getting really close to the Star Trek replicator idea. How far off do you see that?

AR: I wouldn’t be surprised [if it’s] in 10 years.

BG: It’s so hard to predict a technology that changes so quickly. Every year there are new iterations of this 3D printing hardware, and looking 10 generations forward, no one’s going to be able to predict exactly what it looks like in 10 years.

What do you think is going to be the most surprising thing that happens?

BG: Sex toys, custom sex toys. We’ve gotten requests for that, to which Austin will respond, “This stuff is not safe to use in your body, so I wouldn’t recommend doing this.”

AR: What people might not immediately predict—which I would predict—is not going to be one event but many events, which are people younger and younger becoming more CAD literate, becoming more interested in design materials and invention. I think when you reduce the friction to innovation, which is what this software and hardware does, then you’ll have more people inventing awesome things. It sounds like a cliche, but I could see someone inventing the next light bulb—some genius kid whom you give this tool with which he can realize any form.

The democratization of engineering?

BG: Yeah, and as all these things change and manifest themselves, Make Mode will be here to lead you through this brave new world.

To learn more about 3D printing in general or Make Mode in particular visit their website.

Photo via dvanzuijlekom/Flickr (CC BY SA 2.0)